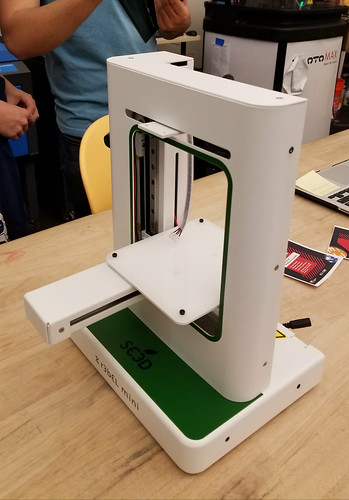

We recently unboxed our SE3D r3bEL mini bioprinter, which we plan to use for research and development aligned with our fermentation science and other biotinkering efforts.

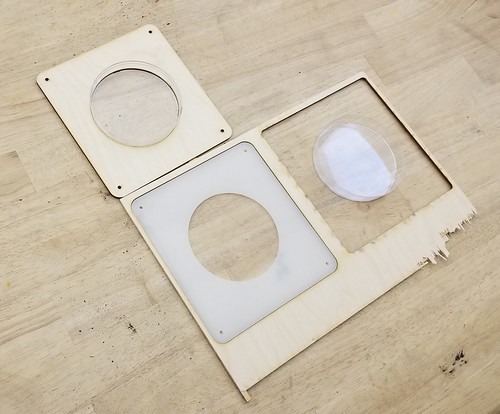

After some initial setup, I realized that the build plate meant to house petri dishes didn’t fit our petri dishes, so I contacted SE3D and asked for a vector file of the shipped build plates so as to modify one. While waiting for the email back, I went ahead and just measured the existing one, and after a few prototypes, I was able to cut a new one to the right size and shape out of acrylic. In the meantime, Vignesh got back to me – they’re very responsive! – with the DXF file of the build plates that arrived with the machine.

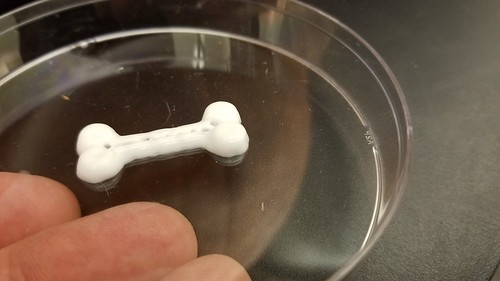

With the petri dish sorted, I set out to print the stock test file. So far, so good.

A successful test completed, I found a *.stl file of Nova (our Innovation Center mascot and the thing we traditionally create using any new machine), imported it into Slic3r, exported as G-code, and fired up the r3bEL. Other than the fact that the syringe ran out of lotion before the print was finished, it worked a treat!

I feel fairly confident in saying that this might be the first time in the history of the world that a rabbit wearing a space helmet was 3D printed out of lotion. #fiteme

Pingback: Biofabrication – The Planting Pot Project – FLC Innovation

Pingback: A New Semester in the Makerspace – FLC Innovation