Inspired by this process for turning SCOBY into fruit leather…

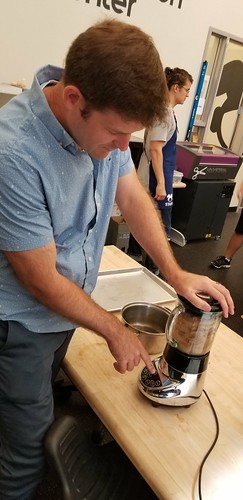

…we decided to prototype a process to turn some mature SCOBY into mush, dry it in a form, and look at the material properties of the finished product. We borrowed a blender and rinsed and blended up a not insignificant quantity of SCOBY, adding a little bit of water to keep things moving.

We weren’t able to find exactly the right vessel, so we improvised, building little dam made of wood to get to the size we wanted.

The material is surprisingly coherent, and the dam acted as a bit of a liquid separator.

The form filled, we stuck it in the oven at 200 degrees Fahrenheit (the lowest the oven in the nutrition classroom will go), and it’s gently baking even as I’m writing this.

In related news, we modified the fermentation chamber, adding a heat mat to see if we can improve the growth rate of the pellicle by increasing the temperature a bit. The mat has a fixed temp, and as it turns out that temp is too high, so we’ll need to look into adding a thermostat to reign that in a bit. Eventually, we plan to construct an Arduino-based, temperature controlled growing chamber that will will log data to a Web-accessible database, but that’s a few weeks out.

Pingback: The Continuing Saga of SCOBY Leather – FLC Innovation