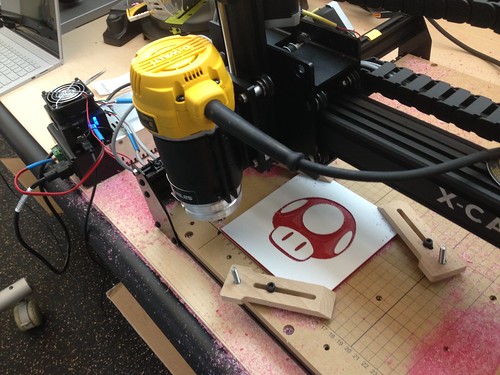

With the floors finished, things are finally getting a little bit closer to normal in the makerspace. Moved the X-Carve from the clean lab to the dirty lab, and tested out cutting some HDPE in preparation for a mosaic tile project.

Lessons learned:

- Slowest router speed is best – less fuzz.

- Even at the slowest speed, there was plenty of fuzz that needed to be cleaned up with an X-Acto knife.

- Pause at your own risk. I paused the cut out of courtesy to the Data Science club, and the job never recovered. When I tried to restart, the X-Carve ignored my pleas. After a while I gave up, and tried to re-run the job using the previously established zero. Things went bad quickly. Easel didn’t seem to care about my prior zero setting, and charged forward, about 6 inches off the mark. I ruined the in-progress HDPE blank, and shaved a little bit off of the waste board besides.

Even with those minor hiccups, I’m loving the final result!

X-Carve Carving – Lessons Learned https://t.co/ThcTp7cUwF First time engraving HDPE. #makered @Inventables