The recent EpiPen controversy led to lots of good conversations this week with various faculty about “medical making,” either as a new class in our upcoming MAKR certificate, a semester-long sort of focus, similar to things like One Book, or as some focus within the larger construct of Making + Doing, which is an idea we’ve been kicking around as a way to intertwine making and service learning. One of the projects that emerged from those conversation is Enabling the Future, an “amazing group of individuals from all over the world who are using their 3D printers to create free 3D printed hands and arms for those in need of an upper limb assistive device.”

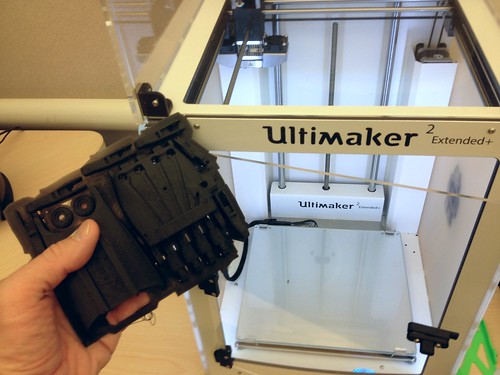

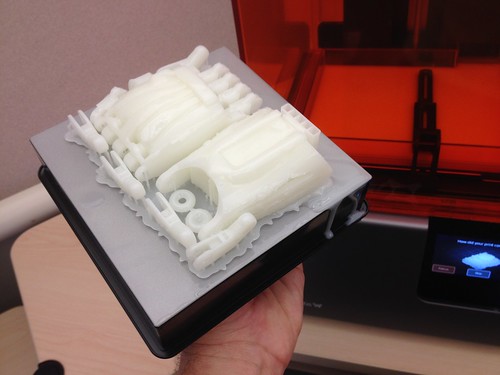

Jennifer Kraemer (ECE) is interested in working such a project into the Making in ECE course she’s developing, so we decided to print up one of the hand systems, specifically the Raptor Reloaded. We set up a job on both the Ultimaker 2 Extended+ and the Form 2, so as to compare time and print quality.

11ish hours later for the Ultimaker…

8ish hours later for the Form 2…

Here’s the initial build of the Form 2 version. The Form 2 resin creates a really nice finished product that takes well to fine tuning with a file.

Here’s the initial build of the Ultimaker version.

I still need to get the screws and wire for the “tendons” to finish them up, but the initial results are promising.

Working on some hands using the Form 2 and Ultimaker 2 E+ https://t.co/4FceNyBefM @Enablethefuture @formlabs @Ultimaker #3dprinting #makered

Pingback: Calculus Models and Learning From Students – FLC Innovation