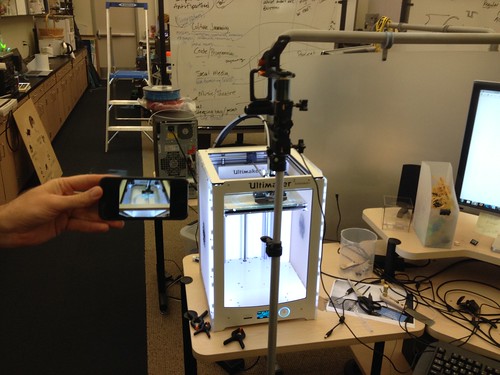

Max and I spent some time in the shop this afternoon, brainstorming Chemistry activities that will make use of the new X-Carve and vinyl cutter, and working on the new Ultimaker 2 Extended+ that arrived the other day. After some tweaking, we got the printer running, and decided to print this Dewalt DWP611 Thread-On Dust Shoe from Thingiverse (CC BY Noah Mackes). Up until now, we’ve been using the X-Carve as a plotter, but Marisa Sayago (Professor, Art) and I have been talking about some printmaking ideas that involved cutting and engraving, hence the need for the dust shoe.

The printer reported that the job was going to take 17 hours, so Max and I decided to set up a webcam and do some R&D on Open Broadcaster Studio, which I have been considering using for the live fishcam that will be part of the aquaponics project. We installed the software, plugged in the camera, put in the YouTube live streaming information, and it all worked perfectly right out of the gate.

By the time I got home, the camera had slipped or been knocked sideways, but the print is still visible!

I’ve been working with technology for many years, but the idea that I can relatively easily monitor from home a 3D print job of a part I need and was able to download for a CNC machine that can be used to support (among other things) hands-on student activities in Chemistry and Art, while simultaneously testing a software program and a streaming service for another project that combines Library, Chemistry, Biology, Theater Arts, fish, and plants is, frankly, pretty neat.

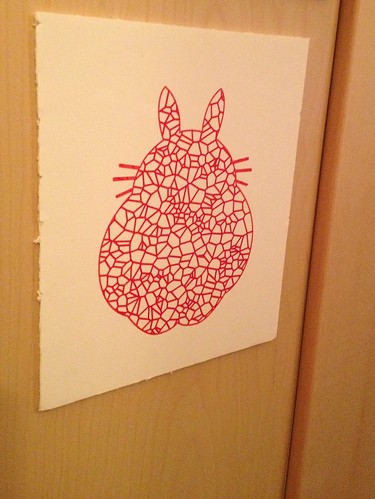

I almost forgot – I made a Voronoi Totoro on the X-Carve (in plotter mode):

CNC + 3D Printing + Streaming Video https://t.co/G7APsHKo9L Live stream (for now): https://t.co/R5DjwPm9Wu #makered

Pingback: Happiness Is A Full Parts Bin – FLC Innovation

Pingback: Printing an OpenBCI Headset – FLC Innovation