The build crew met again this morning for the third and final X-Carve build day.

Finished up the work area, z-axis, drag chains and final wiring…

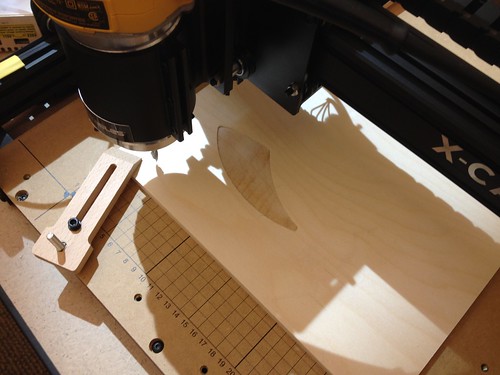

After a few perplexing challenges, especially regarding the mounting of the y-axis drag chain, we were able to finish the build, fire the machine up, and make our first test cuts!

All in all, a very satisfying build, and we learned a lot. For anyone looking to build an X-Carve, I would advise double-checking the forums at Inventables if you run into inconsistencies in the instructions – there aren’t many, but there are one or two differences between the current shipping kit and the videos and build instructions online. I would also advise using the GrabCAD models. We ignored these until the very end, but they proved very useful when figuring out the drag chain mounting, and I wish we had checked them sooner – we pretty much ignored them until the very end of the build.

Potato quality video – I was holding the vacuum in one hand and trying to shoot video with the other, and apparently the iPhone didn’t know upon what to focus):

In the next couple of days, I hope to get the dust extraction situation worked out, and to extend the XYZ wiring so that the power supply can live a little farther from the machine.

Finished! X-Carve Build Day, Part 3 https://t.co/CO2DulFySO @jenniferkraemer @DianeECarlson @Inventables @zkaplan #makered

RT @noiseprofessor: Finished! X-Carve Build Day, Part 3 https://t.co/CO2DulFySO @jenniferkraemer @DianeECarlson @Inventables @zkaplan #make…

Pingback: The Value of Build Days – FLC Innovation