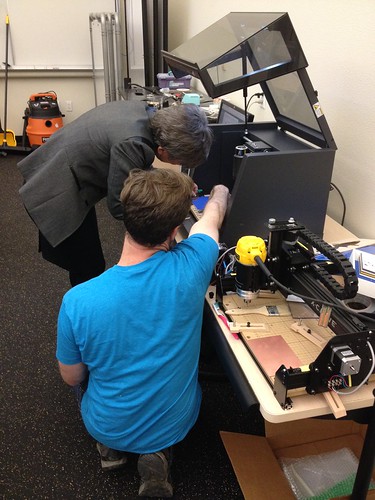

Spent part of the day with these fantastic maker educators from City College of San Francisco. They’re participating in the CCC Maker grant, and visited the Innovation Center to see the space and talk about our makerspace development process. Happy to have made more contacts in the community college maker community, and looking forward to the continuing development of the CCC Maker community of practice.

The laser was installed yesterday, and while makerspaces are more about culture, community, and possibilities than they are about machines, this thing sure is a sweet machine. 🙂

Following the install and orientation, we spent the better part of the day cutting, engraving and scoring wood, paper, and acrylic. Once we got the hang of it, CJ (student) and I decided to push the machine with a test cut through 3/4″ pine.

Ryan and Rick (foreground above) assure me that this much flaring is normal, especially with material this thick (and without air assist, which we’ll probably be adding as funding permits).

On Thursday, March 16, I facilitated an activity about Equity in the Re/Design of Makerspaces as part of a CCC Maker training about New World of Work. Presentation materials below…

Slides:

https://docs.google.com/presentation/d/1Zfpj34dwmmuU7bPEU4YmNOKWqH6ZfbPkn1MiquVbcWs/edit?usp=sharing

Re/Sources:

National Science Foundation, National Center for Science and Engineering Statistics. 2017. Women, Minorities, and Persons with Disabilities in Science and Engineering: 2017. Special Report NSF 17-310. Arlington, VA.

http://www.nsf.gov/statistics/wmpd/

Vossoughi, S., Hooper, P. K., & Escudé, M. (2016). Making Through the Lens of Culture and Power: Toward Transformative Visions for Educational Equity. Harvard Educational Review, 86(2), 206-232.

https://pdfs.semanticscholar.org/fa5b/4e88c78f380b4727d445afa33bea5212a21d.pdf

2016 Student Success Scorecard – California Community Colleges

http://scorecard.cccco.edu/scorecard.aspx

Stanford University d.school

https://dschool.stanford.edu/resources

Sarah Kuhn – Professor Department of Psychology & Center for Women and Work, University of Massachusetts Lowell

https://seadnetwork.wordpress.com/white-paper-abstracts/final-white-papers/thinking-with-things-feeling-your-way-into-stem/

http://thinkingwiththings.com/

After much hemming and hawing, institutional and otherwise, and surprisingly much electrical work:

our first laser cutter – a Universal PLS6.150D with two 60 watt tubes – has arrived. It’s sitting down in Receiving, awaiting an install next week!

There are a lot of pent up projects just waiting for its radiation, so we’re excited to get it up and running and get some things cut and engraved.

Lots of visitors in the past couple of weeks, starting with Oak Ridge High School students, who came to talk about their upcoming hacakathon – http://orhacks.com – and how we might partner. They also drove the Double around.

A couple of days later, we hosted Foresthill High School students, who took a tour of the college and then spent some time in the IC with me to learn about our programs and makerspace development efforts. They’re planning a space of their own, and were eager to hear about everything from gear to floors to furniture. CJ and Alex (FLC students and some of my most skillful assitants) volunteered to help, showing students around and helping them print some stickers on the new vinyl cutter. We also scanned some folks using the Skanect/XBox Kinect setup, which is always a crowd pleaser.

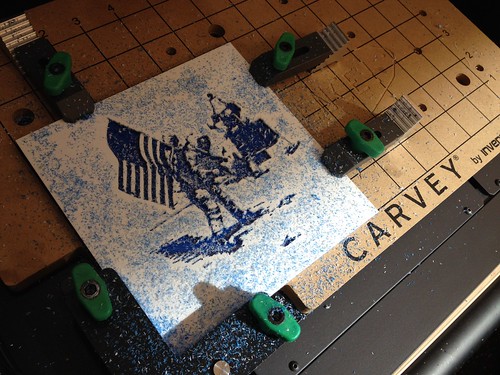

Later that day, about 30 (mostly) 5th graders from Georgetown Makerspace (our sister lab) spent the afternoon in the lab, driving the robot, building with (borrowed) LittleBits, preparing and cutting a tile on the Carvey, getting scanned, and learning about the aquaponics setup.

Busy couple of days, but great to connect with regional maker educators to share information and resources. More photos…

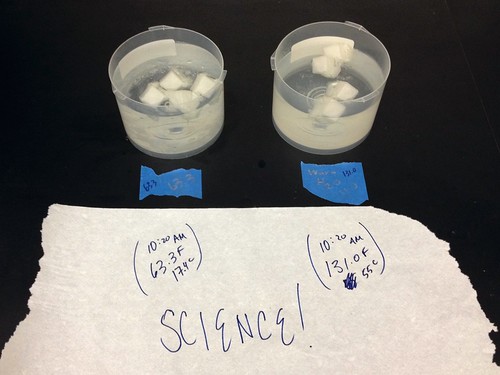

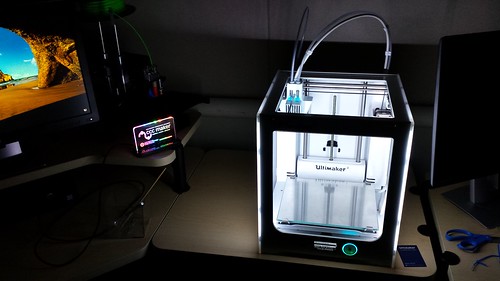

Nathan and Thomas (students) have been printing using the new Ultimaker 3 with the PVA water-soluble support material, and we decided to run a quick little experiment to confirm what we thought we already knew: that warm water would dissolve the PVA quicker than cold water.

After 25 hours, 50 minutes, we pulled both sets out of the water to compare. Turns out that our assumptions were correct, at least for this barely scientific test. Even without any real proper measuring of the leftover gummy PVA on the prints, there was clearly less undissolved support material on the ones initially placed in hot water than on the ones places in room temperature water. I think we’ll borrow a hot plate stirrer from the Chemistry department and maybe try to run a few more controlled and better timed experiments.

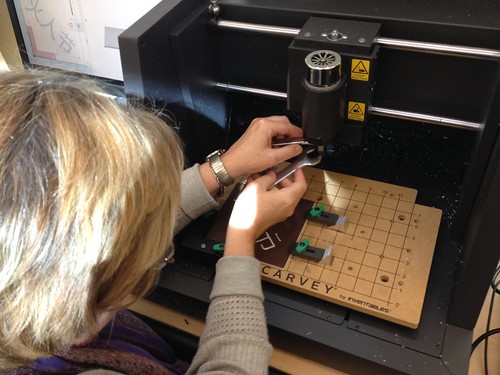

I’ve been working a lot lately with members of Folsom Lake College’s Peer Mentors, a group helmed by the the great Juan Flores (fellow faculty member and father of my lab helper from the other day). The Peer Mentors are working on developing tiles for the mosaic tile project, with the goal that they will in turn help their assigned mentees to develop tiles. It’s our hope that involving new college students in a technical and very accessible project will give them a connection to the makerspace early in their college career, and that having a physical artifact on the wall will help them feel connected to the college. Jess (student, Peer Mentor, and astrobiology enthusiast) was the first student from the group to have her design ready.

The new rough/fine pass feature of Easel is a good one, and should help to preserve the tremendously delicate 1/32″ bits. We actually ended up doing three passes with successively smaller bits, and Jess quickly mastered the process, producing this really nice design.

KC Boylan (Communication and Media Studies) stopped by later in the day to cut her tile…

and Kathleen Kirklin (Interim President) did hers a couple of weeks ago…

The project is turning out to be a great way to foster community as we continue to develop the space, and it’s a maker skills confidence builder besides. With nearly a dozen tiles finished, I need to work with Ian Wallace (Theater Arts) to get some time on the big ShopBot to route out the waffle frame so we can get these up on the wall!

We reached an important milestone in the project this afternoon. The power trio of Nathaniel, Rebekah, and Nathan – the core of FLC’s Data Science Club – got the Raspberry Pi installed and working to drive the integrated monitor, displaying a rolling presentation about the science – chiefly the nitrogen cycle – that makes the aquaponics system work.

As with most prototypes, the presentation needs a few tweaks, but it’s great to see all of the system components coming together.

Nathan is working on the Arduino sensor array, and we’re still waiting to swap the science fish with the aquaponics fish, the latter in the quarantine holding tank in the Innovation Center. The plan is to swap the green arcade button with a blue one, to match the colors in the presentation, and the button subsystem needs some attention, but overall the project is finally starting to feel like it might one day be finished!

Diego, a colleague’s son, was in the makerspace today. He happily spent two hours parting out some old computers, one of which had a floppy drive. I showed him this inspiring video:

I would love to get some floppy disk music going in the lab. After the computers were disassembled, Diego put on the safety gear and went after an old printer.

Safety first!

The new Ultimaker 3 arrived the other day, and Thomas Schmitt (student) unboxed it and got it set up and calibrated. Thomas has been designing a bobbin for fly fishing fly tying, and some of the project parameters, including a threaded rod and a hollow tube that serves as a thread guide, seemed to provide a good test case for a first print on the U3. The machine comes standard with dual extruders, and ships with a roll of PVA, a water-soluble filament.

The first print came out really nice, and the water-soluble support material is a game changer, especially for printing certain fine details and hollow areas. Some of the tricky biology models that faculty want to print are finally going to be within reach.