Katia (student and President of the Asian Pacific Islander Club) collaborated with Innovation Center on a katazome activity for her club. Katazome is a Japanese fabric dyeing process that uses a resist paste applied to fabric through a stencil, and we more or less followed the procedure detailed in Workshop no. 21: Natural Selections: Hands-on Katazome and Indigo with Graham Keegan.

Early this morning, Katia made the dough using rice flour and rice bran…

…which we then steamed for an hour and half.

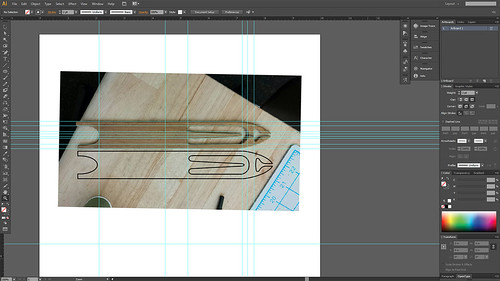

Meanwhile, we used the laser cutter to cut out some stencils, based on traditional Japanese designs.

While Katia smashed up the now cooked dough balls, adding glycerine and water with hydrated lime to make a paste…

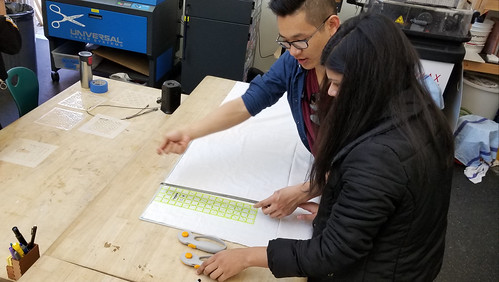

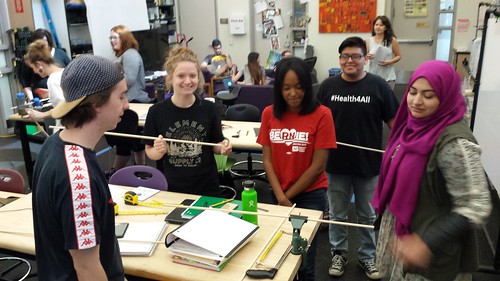

…other members of the club arrived, and set to work cutting cotton fabric into 8″x8″ squares…

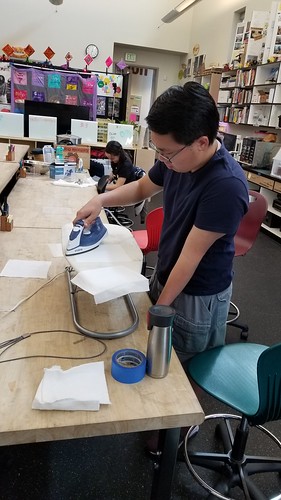

…and ironing the fabric to make it nice and flat for stenciling.

The paste ready, students set to work applying it to the fabric…

…and hanging the squares up to dry.

Once the squares were dry, it was into the dye for 20 minutes…

..then back on the line to dry again…

…before being rinsed.

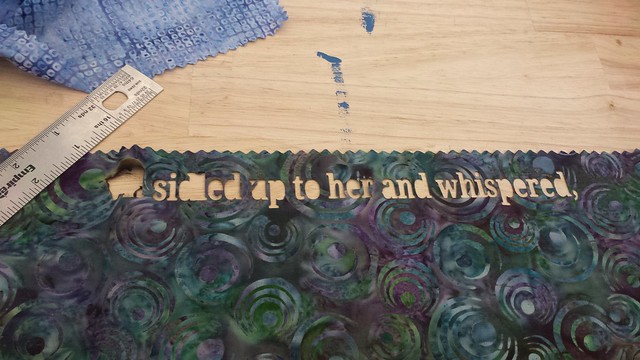

The rinsed pieces now dry, Katia trimmed the edges with pinking shears…

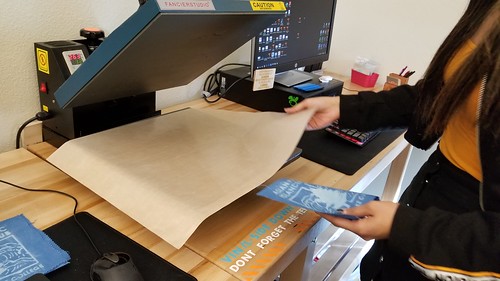

…while other students pressed the finished squares using the t-shirt press in the Clean Lab.

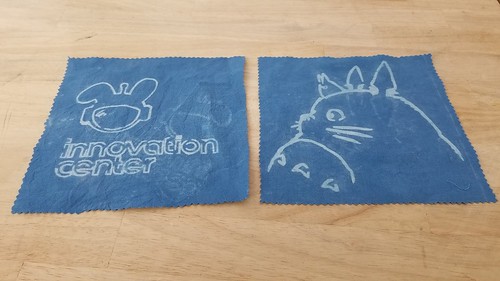

The result!

It’s exciting to find ways to combine traditional arts – katazome – with digital fabrication – the laser cutter – and we’ll incorporate what learned (a lot!) about the process and timing into v2.0 of the activity in a couple of weeks.

More photos from the activity: