An update on the sheet SCOBY we harvested the other day…

Pro Tip: Don’t dry your SCOBY directly on plywood.

The very fine underlayer SCOBY we placed on a sheet of plywood, having seen that technique in a video somewhere – YouTube, maybe? Anyhow, the SCOBY and the plywood largely became one, and so we were only able to get a few pieces of fine parchment-like paper.

The rougher top layer we draped over cardboard, and while it dried without sticking, it’s a much more fragile product than the original piece we dried some weeks ago.

Fortunately, we’ve got another big sheet growing, so we’ll look at different ways to dry it, and to remove it from the tea solution without letting it separate into layers.

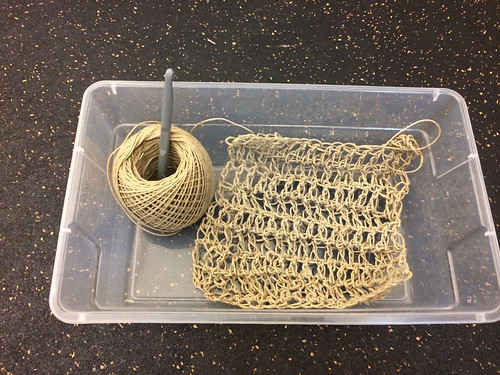

Meanwhile, we’ve discussed different ways that we might incorporate other materials into the growing SCOBY, and landed on the idea of somehow incorporating woven natural hemp twine into the process, and seeing if the bacteria and yeast will colonize the twine. Workshopped the idea with Clarity (student, Innovation Center staff, and fiber arts expert), and she proposed the idea of crocheting the twine to produce a mat. Having no crochet hooks in the shop – we need to remedy that – she found a model and printed one, and set to work creating the mat.

Work in progress…

I think we’ll boil the finished product to sterilize it, and then float it somehow at the surface of a kombucha batch, and see what happens.