Earlier this week, Diane Carlson (Sociology) and I held a preview event for Making Social Change, our Sociology + Making course, as part of FLC’s Social Justice Spring events. We decided to create some drop spindles and spin some yarn, based on an activity Erica Tyler (Anthropology) developed as part of last summer’s Making Across the Curriculum faculty professional development program.

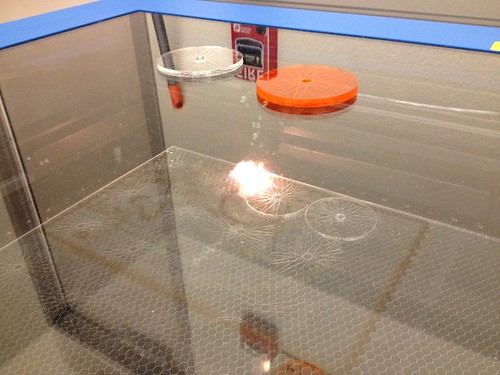

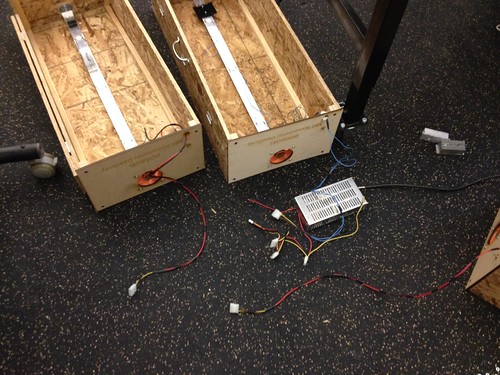

We cut the whorls using the laser cutter (which has been christened “Danger Scissors”)…

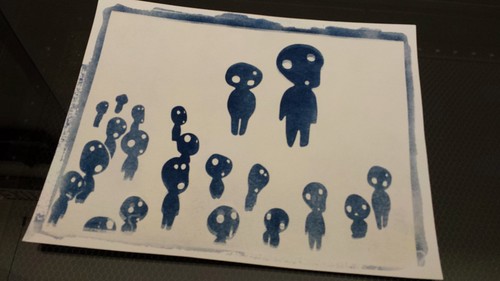

Note the engraved design, inspired by Gandhi’s spinning wheel. Diane cut the dowels using a good old-fashioned chop saw…

…after which she and Erica taught us how to turn wool into yarn.

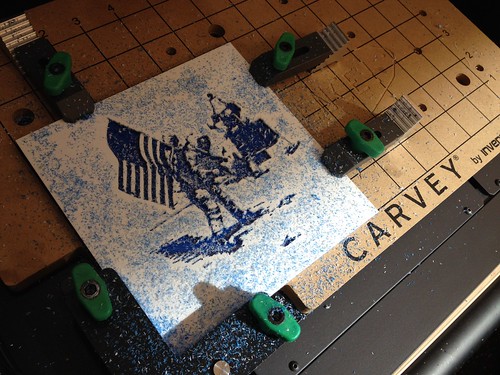

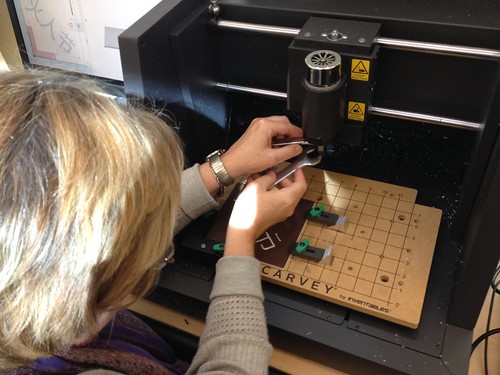

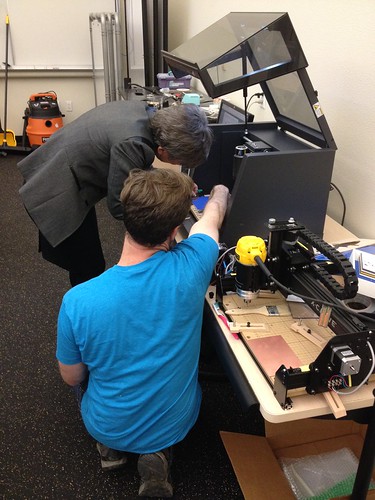

We also walked students through some other digital fabrication techniques, using the same spinning wheel motif source file to create objects using the Carvey, vinyl cutter, and 3D printer. Looking forward to helping bring this course to life in the fall!