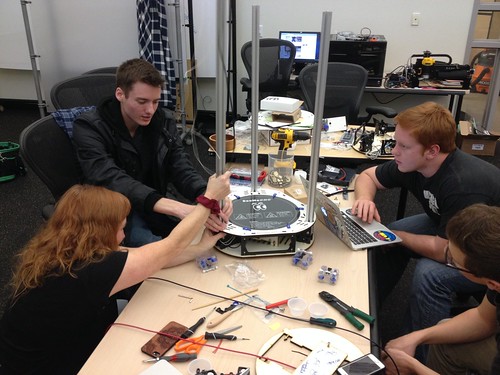

I’ve been working a lot lately with members of Folsom Lake College’s Peer Mentors, a group helmed by the the great Juan Flores (fellow faculty member and father of my lab helper from the other day). The Peer Mentors are working on developing tiles for the mosaic tile project, with the goal that they will in turn help their assigned mentees to develop tiles. It’s our hope that involving new college students in a technical and very accessible project will give them a connection to the makerspace early in their college career, and that having a physical artifact on the wall will help them feel connected to the college. Jess (student, Peer Mentor, and astrobiology enthusiast) was the first student from the group to have her design ready.

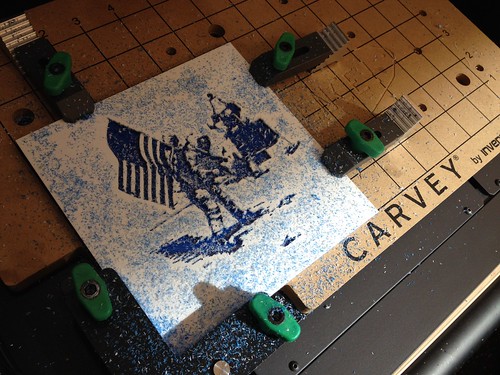

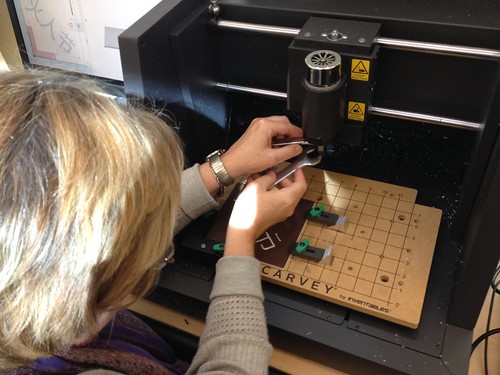

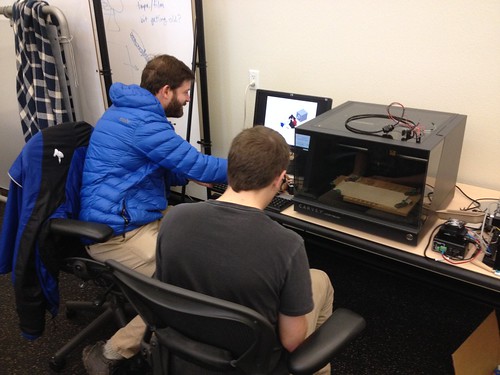

The new rough/fine pass feature of Easel is a good one, and should help to preserve the tremendously delicate 1/32″ bits. We actually ended up doing three passes with successively smaller bits, and Jess quickly mastered the process, producing this really nice design.

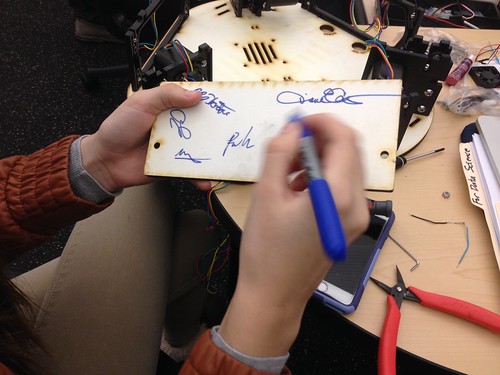

KC Boylan (Communication and Media Studies) stopped by later in the day to cut her tile…

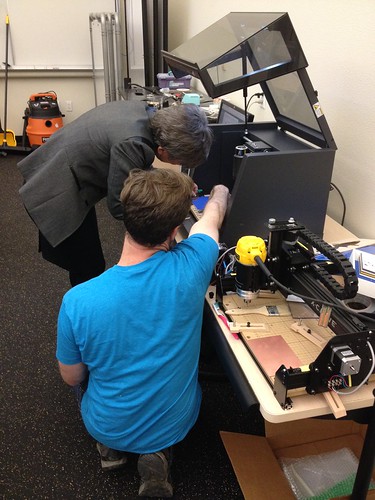

and Kathleen Kirklin (Interim President) did hers a couple of weeks ago…

The project is turning out to be a great way to foster community as we continue to develop the space, and it’s a maker skills confidence builder besides. With nearly a dozen tiles finished, I need to work with Ian Wallace (Theater Arts) to get some time on the big ShopBot to route out the waffle frame so we can get these up on the wall!