Stalwart champion of innovation Jason Pittman (Professor, Geosciences) – he of the long-term Innovation Center/Geosciences KAP/BAP/Quadcopter collaboration dolookdown.org – and I have been discussing uses for 3d printing in geology, geography and GIS. Most recently we’ve been looking at Terrain2STL (http://jthatch.com/terrain2stl/), which generates an STL from a selected area in Google Maps. Haven’t had time yet to print from there, but we did have a chance to print this sweet pre- and post-eruption model of Mount St. Helens (CC BY-NC-SA, by Tree_House_Fire:

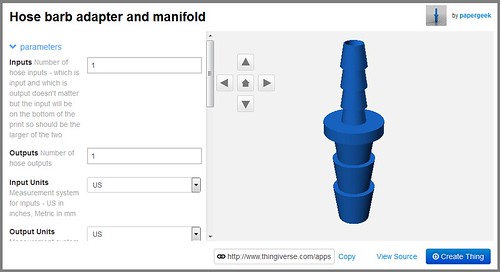

The venturi in the tower aquaponics system doesn’t seem to work reliably. I’m guessing that the inner pathway keeps getting blocked, either by artifacts of the printing process, or with gunk pulled in from the water. In any case, I’m going to try a different approach. Specifically, I’m going to put a small pump in the tank, and have that on a timer, periodically flooding the bottles. To do that, I need to connect tubing of various diameters. I poked around on Thingiverse and found this hose barb adapter and manifold (CC BY-SA, by papergeek).

A few tweaks in the Customizer, and I’m able to print essentially any barb I need. Using a 3d printer to print objects to demonstrate 3d printing is one thing, and using a 3d printer to print useful objects for immediate use in a project is something altogether different – something like a miracle.

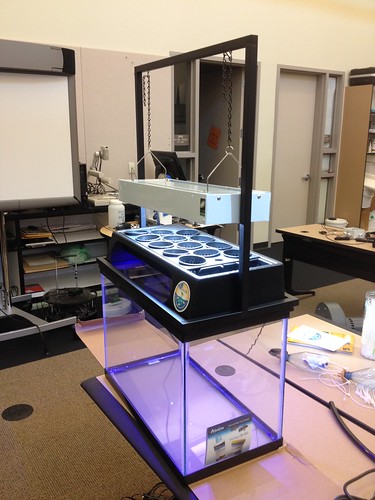

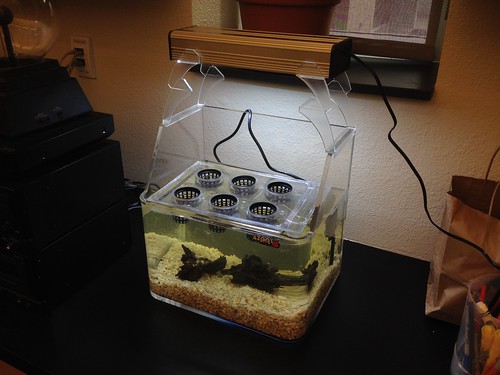

The project is slowly coming together. Yesterday, the ECO-Cycle Aquaponics Kit arrived!

We’re taking some shortcuts with phase 1 of this project, combining kits where available, in an effort to shorten some of the development time and get to a public roll-out sooner. Now that we have the actual setup, we can proceed with the final design phases of the tank base, which will include some variation on the nitrogen cycle diagram. Max Mahoney (Chemistry) has the pH test solutions ready, so hopefully next week we can get the sensor array working. In other news, I heard from IT, and they’re coordinating with the electricians to complete the network drop when the Library floor is opened up for the electrical work. Slowly but surely…

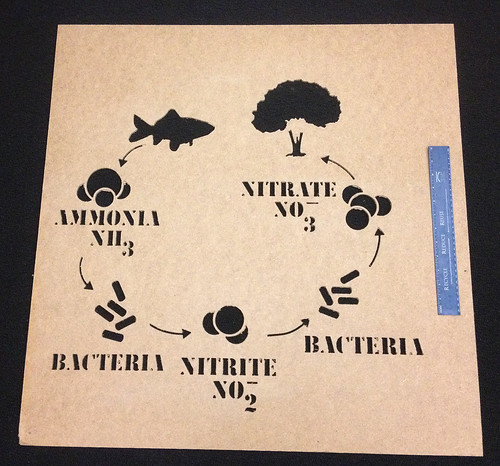

Made some spectacular progress on the aquaponics project, producing a prototype of what will eventually be the light-up infographic built into the base. The team collaborated on a design for a diagram of the nitrogen cycle, and with the help of Ian Wallace (Professor, Theater Arts) and Cameron Hoyt (student and designer of the tank stand), we were able to get the design cut out on the big ShopBot in the scene shop.

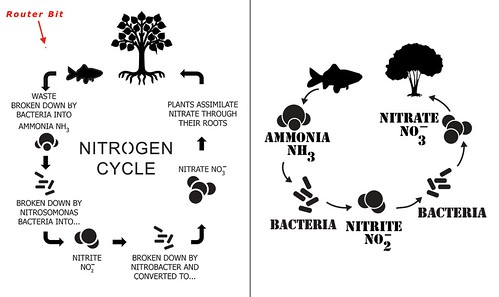

Tools have their own logic, and CNC is no different. Balancing legibility of the design with the properties of the materials and the constraints of router bit size was a learning experience. The initial design was text heavy, but the 1/8″ bit introduces some size constraints. That is, the text has to be large enough for the machine to cut. After consulting with Ian, I scaled up many of the lines, adjusted the font, and created a little 1/8″ dot to drag around the image as a simulated router bit. The original is on the left, with the revised version on the right (below).

Ian took the draft diagram and ran it through software to create the tool path. Some scale work still to be done, especially on the text, but we decided to run a test cut anyhow.

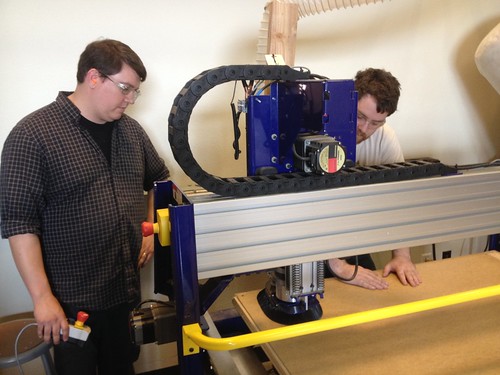

I watched and learned as Cameron and Ian set up the ShopBot and got things ready to carve…

…after which I babysat the machine, which took about 30 minutes to cut out the prototype.

Below is the prototype, after a little cleanup with a knife, sandpaper and a file.

There’s still some design work to be done, and some tightening and scaling to make the diagram legible, but we were very pleased with this rough version. Always be prototyping!

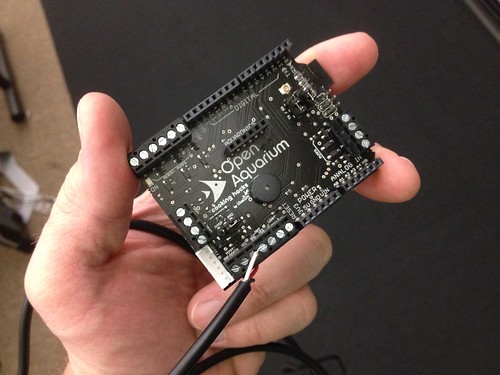

The gear is beginning to roll in! As with any reasonably complex endeavor at any reasonably complex institution, procuring the “stuff” to make a project work takes a great deal of time and energy – lots of rules and forms and budget strings and signatures and hoops to be jumped through. For this particular project, the electronics – chiefly Arduino shields and associated sensors – are sourced from a Spanish company called Cooking Hacks. We chose this particular system because a) the parts seem to be well integrated and seemingly well thought out, and b) Cooking Hacks seems to have the code worked out, not just for the shields and sensor interfaces, but for the server-side bits that make the web integration work. In short, the goal is to get a prototype up and working with a minimum of coding and fuss, and the Cooking Hacks gear seems to fit the bill.

I was able to get most of the sensors working in relatively short order, so I’m feeling good about the progress. Still waiting on the purchase order for the tank itself, and the ECO-Cycle Aquaponics Kit for the top, but we were able to get a small test tank up and running, thanks to some spare parts the Biology Department was able to scrounge, and some help from Max Mahoney (Chemistry).

In addition to the little aquaponics setup above, we gathered up another unused 23-gallon tank, complete with filtration and gravel and all the parts necessary to bring up a complete “development instance” of the project in the Innovation Center, which we’ll use to test the electronics, and to get the water and filtration and fish and procedures sorted out. Progress!

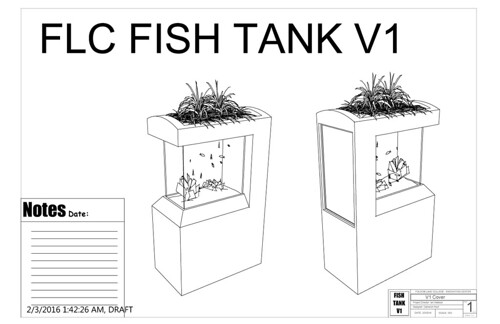

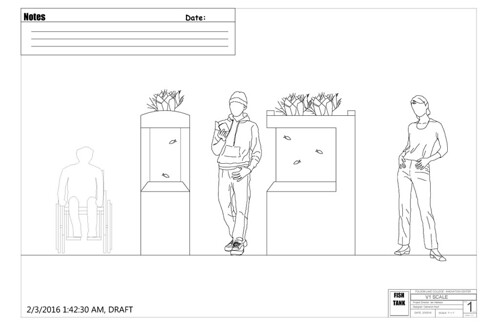

Met with Cameron Hoyt (FLC Theater Arts student and primary design and construction resource for the project) to go over some initial design drawings. We talked through a bunch of considerations regarding size, scale, construction, safety, design, integration with the space, ease of access, cable routing, and other things. I’ll be seeking input from the other project primaries – Biology, Chemistry, and Library faculty – as we further refine the project and enter the build phase.

As part of Social Justice Spring, Diane Carlson (Sociology) and I presented a preview of the Making Social Change course we’ve been working on. Here’s a description of the session:

Join us for an interactive preview of a new course that will explore the intersections of social movements, technology, tools, and the maker movement. Come create, consider, collaborate, and culture jam!

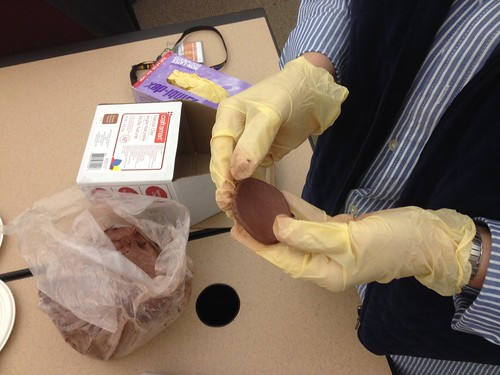

Seed bombs…

and scrambled Bratz…

Presentation slides: https://docs.google.com/presentation/d/1SJTDnYs5oQglkyKP2CmsIKoqzbnU2IGkklahQrPKVB8/edit?usp=sharing

Making Across the Curriculum: The Modern Maker Movement & Interdisciplinary Innovation

Zack Dowell

Folsom Lake College Innovation Center

Presentation Slides: https://docs.google.com/presentation/d/1aLTLU_dZL2yjY2i3b1HGOk1T9wIw3H2B5DZY50_li2o/edit?usp=sharing

Conference Information – http://www.asccc.org/events/2016-01-21-160000-2016-01-23-220000/2016-instructional-design-and-innovation

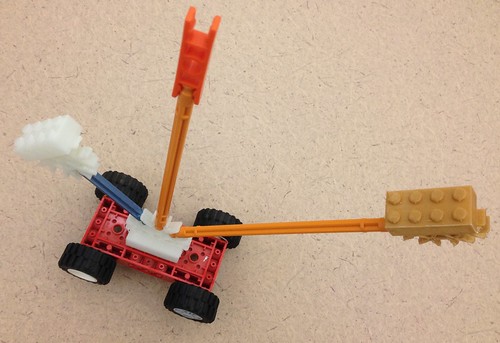

Legos and k’NEX – and people – working together with the help of the Free Universal Construction Kit.

Professor Jennifer Kraemer (Early Childhood Education) and I recently collaborated on a lesson plan to use 3D printing in the ECE classroom. Specifically, the project uses the Free Universal Construction Kit, a set of printable interfaces that bridge 10 common proprietary building systems including Lego, Lincoln Logs, Tinkertoys and K’NEX.

The full lesson plan can be found here: https://docs.google.com/document/d/1GVfIXhJFxgTq3lA5-n3uwT9XyLTdKMayLcqPaE36VCc/edit?usp=sharing

We hope to test it out in ECE 342 – Constructive Math and Science in Early Childhood Education.