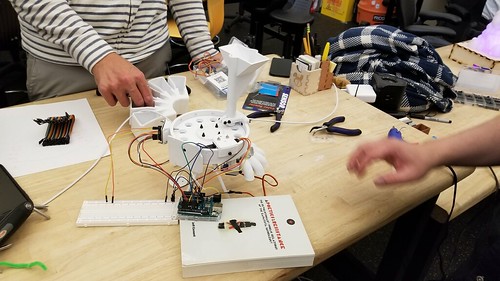

With the semester over, we’ve had some time to regroup and plan for the fall. One of our main goals this summer is to make sure that each staff member is comfortable on each fabrication process and machine. To accomplish this goal, the person most fluent in a particular process – 3D printing, or woodworking and power tools, for instance – is responsible for cross training all of the other staff.

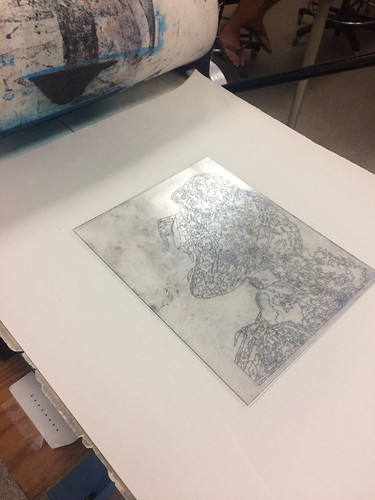

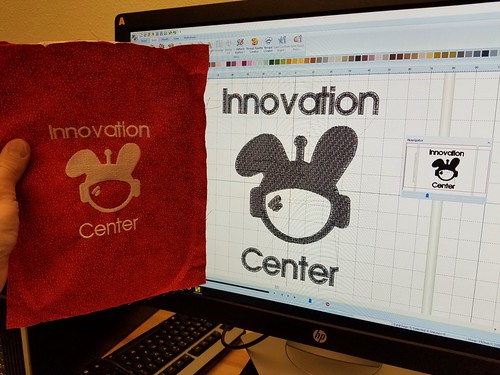

Clarity (student and makerspace staff) is an accomplished fiber artist, and she’s been the point person for sewing in the Innovation Center since the Making Social Change class last fall. Her group created the A-Z of Planned Parenthood quilt for their final project, and she has become quite skilled at using our Baby Lock embroidery machine, most recently using it to create the embroidered bean bags…

…for the cornhole game we brought to Maker Faire.

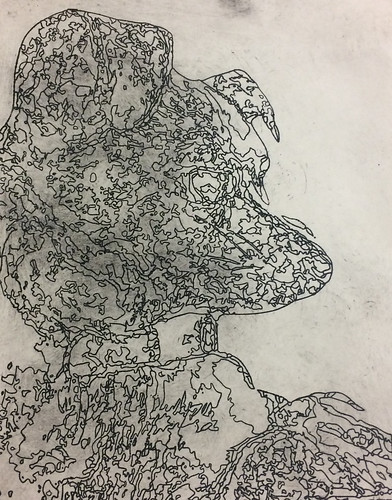

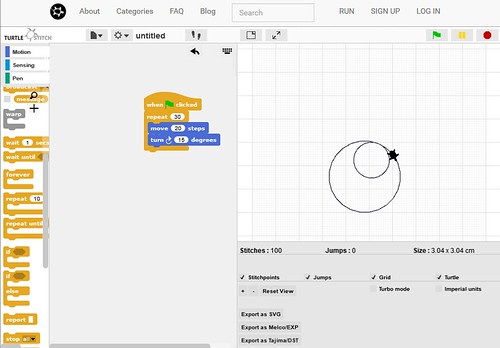

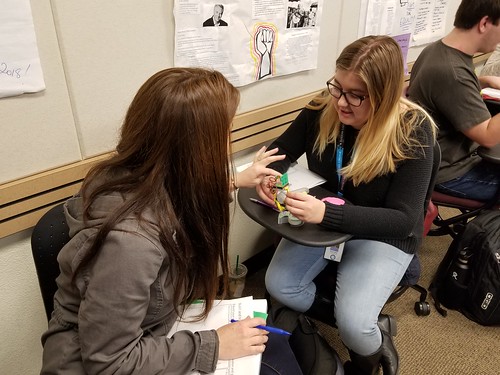

As the resident expert, she’s been training up the other staff, and today, she spent the day working with Nicole (student and makerspace staff) to create a really amazing canvas tote with an image of Nicole’s Mom’s cat on it. Requiring multiple thread changes and lots of tweaking in the embroidery software, it took quite a while, and Nicole now feels confident in helping makerspace visitors through the embroidery process. The resulting artifact is truly magnificent!

flickr gallery of work-in-progress photos: