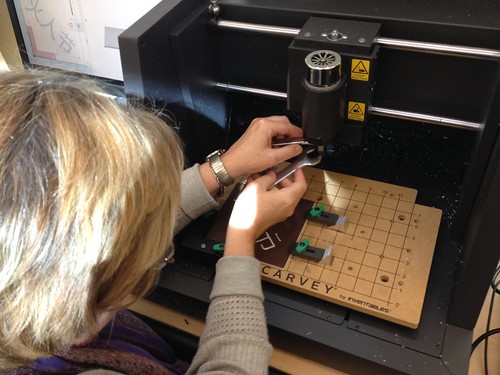

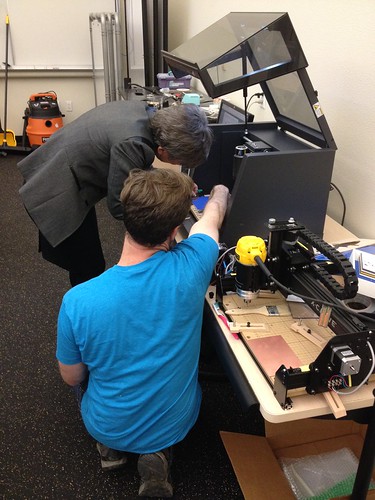

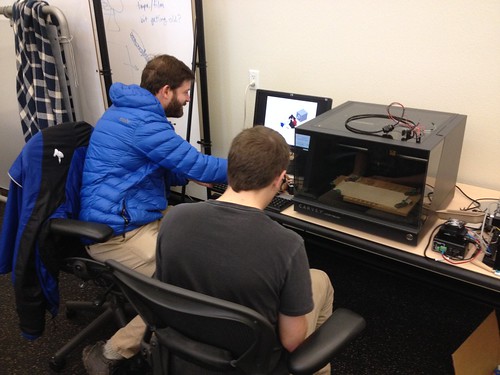

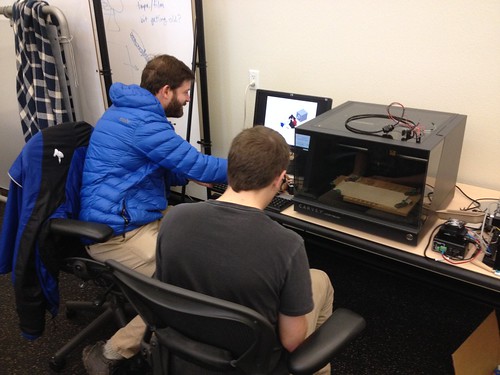

Assembled a team of faculty and students to continue work on the Rostock Max v3 (part 1, part 2). As before, the project is nicely modular, so while Max (Chemistry) and CJ (student) worked on the electronics…

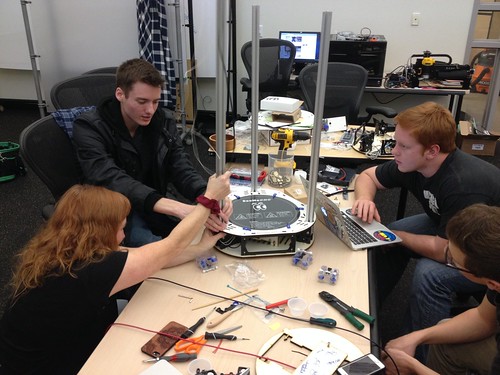

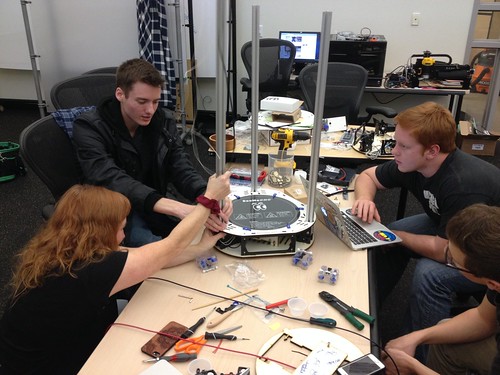

…Diane (Sociology), Alex Hartigan (student), and Thomas Schmitt (student) focused on the main assembly.

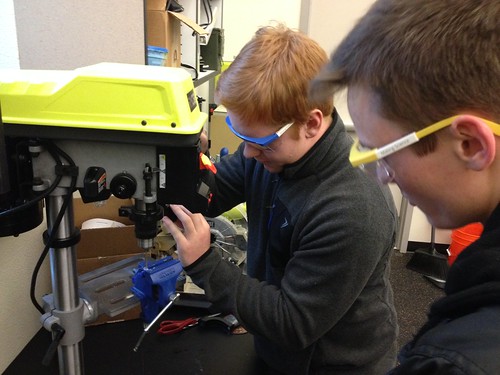

As it turns out, instead of three each of the inner and outer bits that hold the bearings for the carriage, the kit included four and two. We talked about some options, and the crew decided to mod one of the errant parts to make it work, which involved sawing off a bit of it…

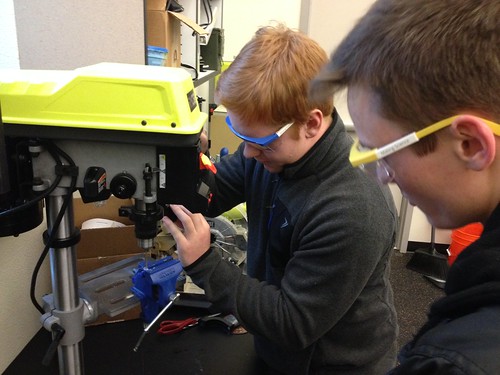

…and drilling a couple of holes…

…while I contacted the vendor about sending a replacement. We think our modified part will work, but I’m working on getting the right part sent, just in case.

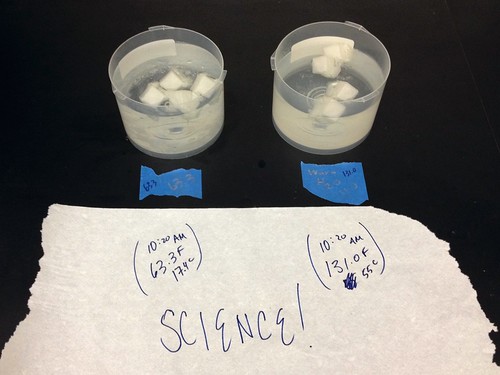

Meanwhile, Taylor (student) dropped by to test the water chemistry of the in-progress aquaponics installation.

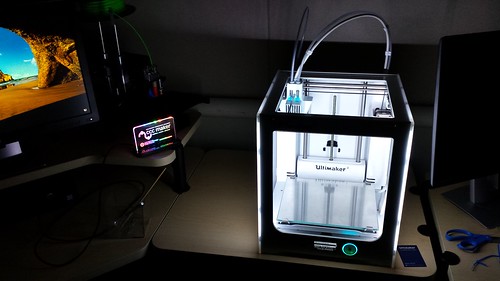

We’ve probably got at least another day of work before the printer is finished, and as folks began drifting away, Levi (receiving) delivered 12 new lab stools. CJ, Alex and Thomas hung around and helped assemble them.

Still waiting on the workbenches, which should be here in the next couple of weeks. Lots of energy, and lots of making!