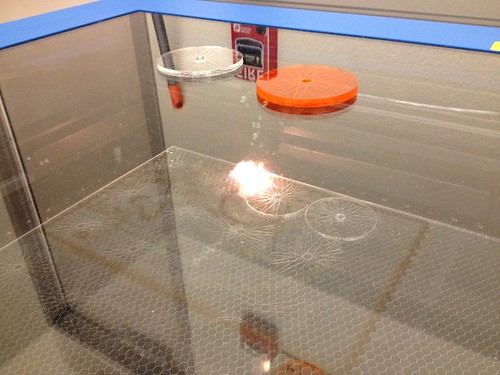

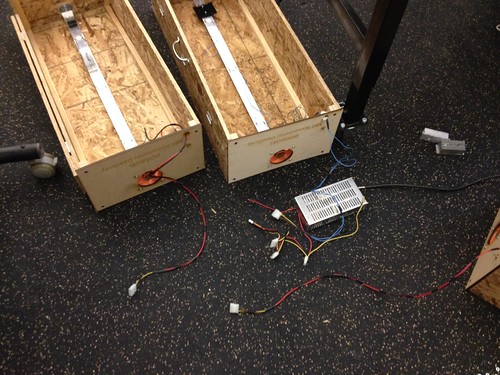

The pieces we ordered to build the volumetric display for Chemistry visualization finally arrived! With the help of CJ, Nathan, and Rebekah (students), Max (Chemistry) got everything cabled up…

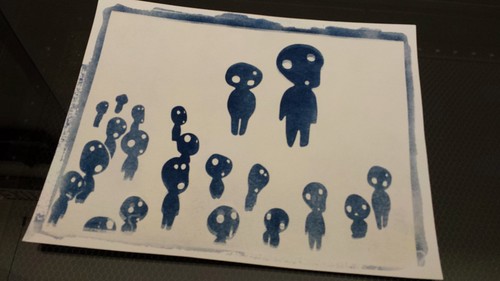

Using bits from our original prototype, Max fired up a molecule, and it works!

In order to better enjoy the three dimensional holographic molecules, we quickly cooked up a little blanket fort…

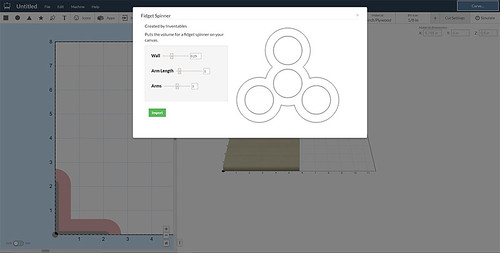

Now that we have the parts in place, we can move on to developing the enclosure and making the system portable. It’s great to have the space, tools, and people to be able to turn good ideas into working prototypes, and we’re looking forward to making quick progress on this one (finally).