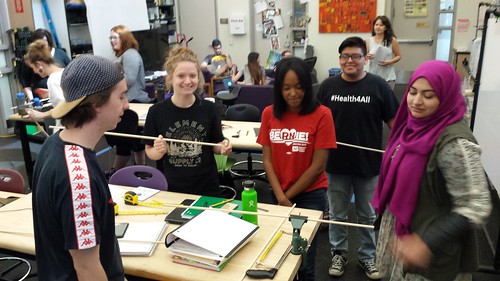

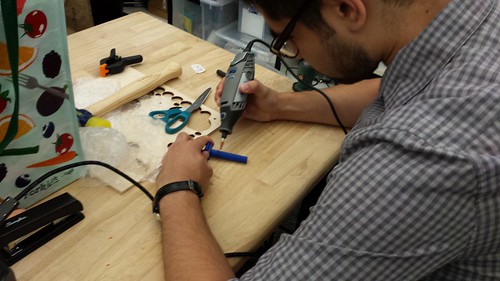

On Friday, May 5, the Innovation Center Makerspace Student Advisory group held a planning retreat in the Innovation Center Makerspace. Rebekah, Nathaniel, CJ and Nicole are four of the college’s most engaged students, and they have been actively involved in the growth and development of our makerspace.

After some general discussion about planning mechanics – we agreed to continue using Slack (for team communication), Google Drive (for document sharing), and Asana (for project and task management) as our planning and communication toolset – we moved through some brainstorming and discussion in the areas of Operations, Marketing and Outreach, and Makerspace Programs, all in preparation for our fall opening, and all against the backdrop of the statewide CCC Maker Grant.

On the Operations thread, we talked about onboarding of new students, facility and machine access issues, safety and training, facility usage tracking, and protocols around equipment upkeep, maintenance, and supplies.

Moving on to Marketing and Outreach, we discussed the development of an Innovation Center Makerspace brand, including logo, typography, colors and a style guide, and an outreach plan, including the potential for a “makerspace student ambassador” program, classroom presentations, involvement of student clubs and organizations, and activities leading up to our grand opening event in the fall.

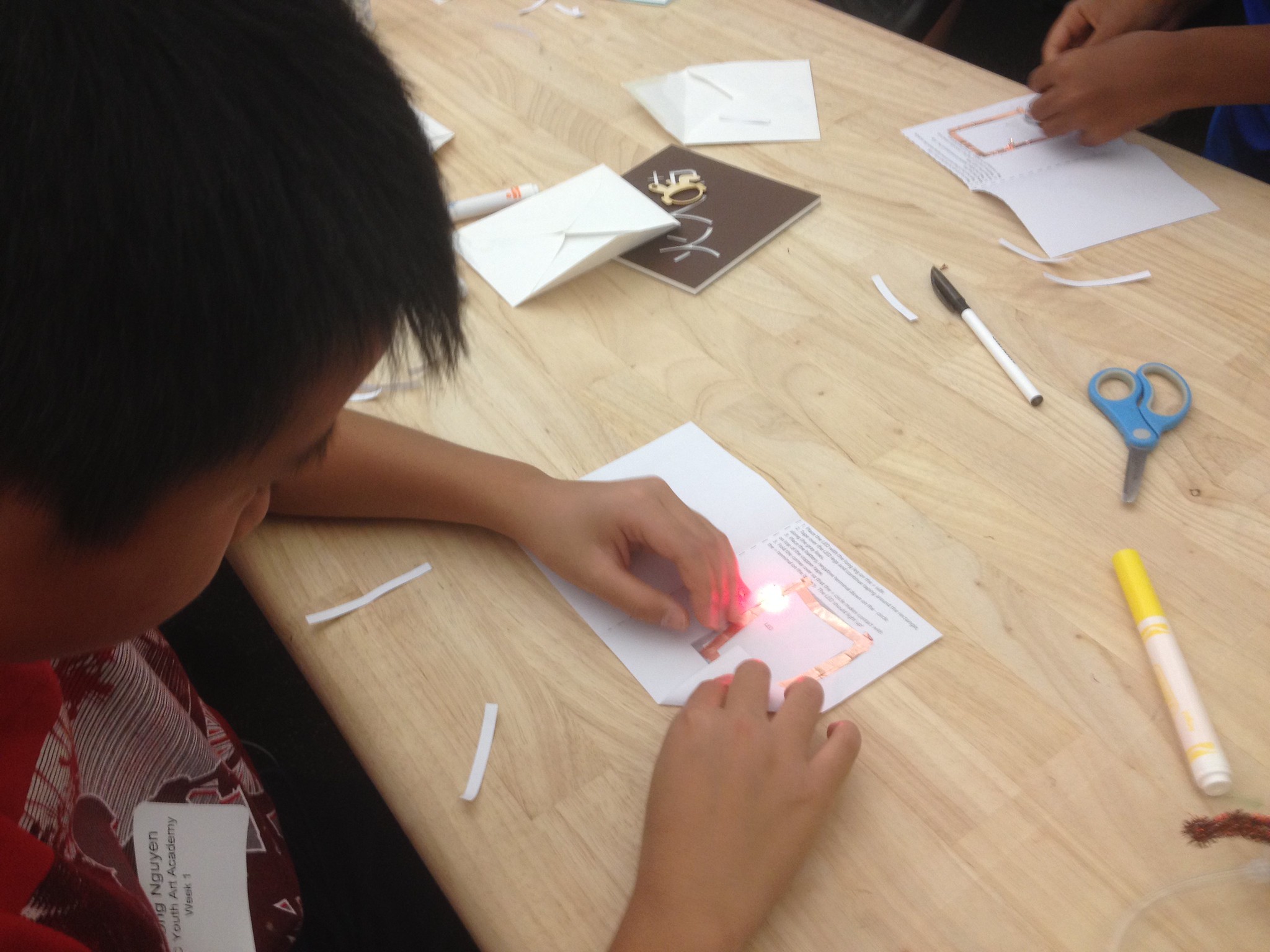

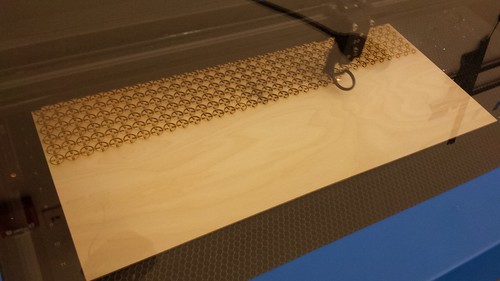

Finally, we did some brainstorming around the theme of Makerspace Programming, and generated ideas including hosting coding and other bootcamps, eSports tournaments, mini Maker Faire participation, 1st Friday “What I Make” sessions, the proposed Makers in Residence program, and integration with Science Center and other collegewide activities (like the recent cyanotype activity, March for Science sign making, Social Justice Spring event, and International Workers’ Day march and ceremony).

Feeding our planning efforts are the data from a survey adapted by Nathaniel and Rebekah from one Sierra College has used in their own makerspace planning efforts. We’re still analyzing the survey results, but my favorite response so far, in answer to a question about what students find appealing about makerspaces:

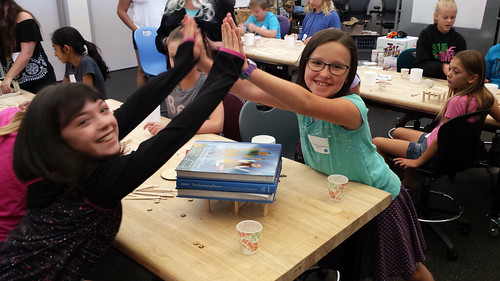

“Real life application. We study so much theory and it would be nice to engineer something.”

The student voice is critical in the development of makerspace programs, services, and culture, and we’re lucky to have such a dedicated and engaged group of students to help guide our growth.